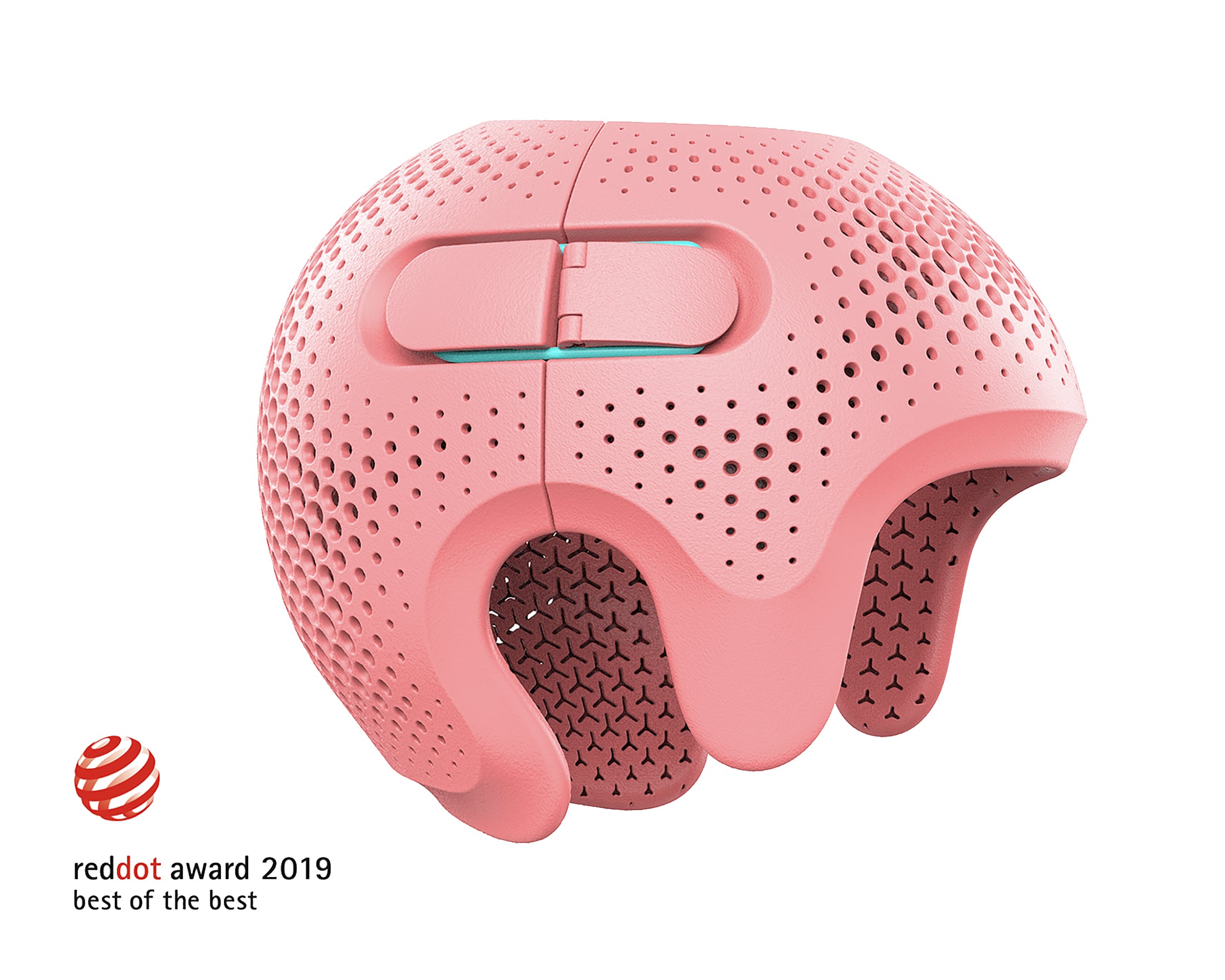

What does a cranial remoulding orthosis has in common with products from companies such as Apple, Audi, LG, Philips, Ferrari, or Porsche? Like them, Talee®’s designers have been recognized for their contribution through one of the world’s most prestigious design awards. Talee®'s cutting-edge 3D printed design won the Red Dot: Best of the Best for an outstanding product setting world design trends.

Red dot ranks among the world’s largest design competitions and has been held for over 60 years. The jury shortlisted only a few dozens of products – about 1% - from more than 5500 applications from 55 countries for the Best of the Best award. In addition to attention to quality of design, jury experts assess the innovativeness of the product and its potential to impact specific segments of healthcare globally.

The company’s goal is to bring completely new products to baby patients around the world, offering much higher comfort, functionality and aesthetic appeal.

“The aim of our devices is not only to effectively treat babies, but also to break down prejudices that medical devices are uncomfortable products and having to use them is a necessary evil. We realize that the psychological side of the treatment is no less important for our patients and their parents, and we are therefore trying to keep one step ahead of other companies in the field by offering patients modern products that resemble fashion accessories rather than medical devices. Standard cranial remoulding orthoses are often bulky, heavy and uncomfortable. This is due to the limits of the manufacturing technology commonly used in our industry. That’s why we have decided to use 3D printing, which gives us the freedom and opportunity to manufacture nearly anything.” says Ales Grygar, Talee®’s chief designer and Red Dot: Best of the Best award recipient.

Talee® uses advanced technologies such as 3D scanning, 3D printing and algorithms to manufacture its devices. “We’d been having the vision of 3D printed cranial remoulding orthoses for a while, but it was only after the arrival of the 3D printer by HP that we finally found a strong manufacturing partner who offered us high quality and fast printing at reasonable prices. With this technology, we are able to fulfil our ambition – to become the global technological leader in the field of custom-made orthotics.” concludes company’s CEO - Dr. Jiri Rosicky.